Call This Wednesday to Get $25 OFF

Clean Solutions, Dirty Jobs – Done Right. Reliable. Responsive. Remarkable.

Call This Wednesday to Get $25 OFF

Clean Solutions, Dirty Jobs – Done Right. Reliable. Responsive. Remarkable.

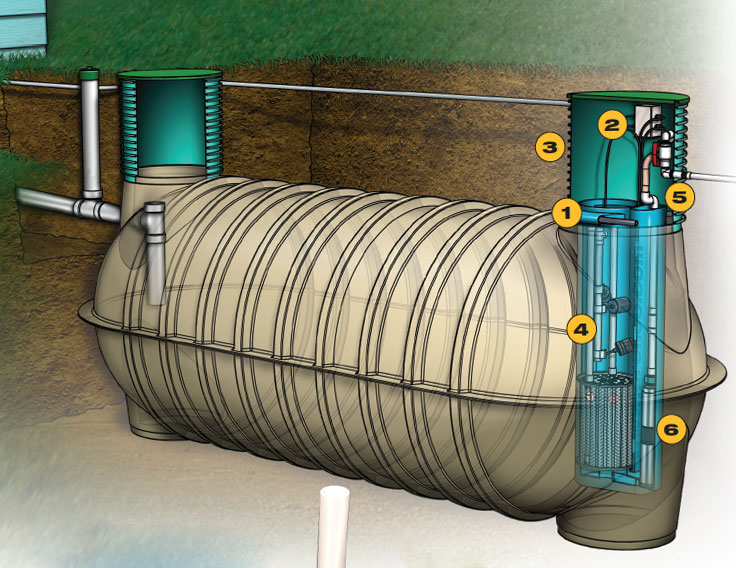

When contemplating sewage treatment, the average person’s thoughts rarely delve into the intricate world of lift stations. Often overshadowed by the grandeur of treatment plants, these unassuming stations play a crucial role in the sewage journey. Positioned as the terminal destination after traversing miles of underground pipelines, lift stations use pumps to elevate waste above ground level for further processing. However, despite their hidden nature, lift stations are not immune to various challenges that can impede their functionality. As a reputable septic company, Septic Connection provides the top five lift station problems and how to tackle them effectively.

One of the most pressing issues affecting lift stations is insufficient capacity. The constant influx of wastewater can overwhelm the station’s pumping capabilities, leading to potential backups and overflows. To address this, regular capacity assessments are paramount. Our expert septic tank repair team conducts thorough evaluations to ensure the station’s capacity aligns with the community’s needs. We can recommend upgrades or expansions to accommodate heightened demand if deemed inadequate.

Efficiency is a cornerstone of lift station operation. Inefficient stations consume excessive energy and can cause uneven wastewater flow distribution. Regular check-ups on pump performance, power consumption, and overall functionality by a trusted septic tank repair service are vital. Implementing state-of-the-art sensors and control systems can provide real-time insights into station operations, enabling proactive adjustments to enhance efficiency.

Elevating sewage above ground level for discharge can pose challenges, particularly where geography poses limitations. Discharging at higher elevations requires more energy and strains pumps. Our septic company offers innovative engineering solutions, such as pressure-reducing valves and alternative discharge paths, to rectify this issue. It is advisable to collaborate with local authorities or septic tank installation experts to seek suitable discharge elevation regulations.

The septic system is an onsite waste treatment facility, and it is incredibly reliable. However, the system is only as effective…

Imagine flushing your toilet and then suddenly realizing that your backyard has turned into a swampy mess. This unpleasant experience is…

Soil testing is a critical step in various construction and environmental projects. It provides essential information about the ground conditions, which…

Grease traps are remarkable tools that help keep your establishment clean and free from bad odors. Septic Connection has a…

If you have just moved into a new home or property that relies on a septic system for waste and wastewater…

Lift stations are notorious for emitting foul odors, disrupting the surrounding environment. To mitigate this, consult a professional septic tank installation service for odor control measures. We can install odor-reducing technologies, such as activated carbon filters or chemical scrubbers, eliminating odorous compounds before they escape into the atmosphere. In addition, regular maintenance by a septic tank pumping professional curbs smelly emissions.

Bypass gates are crucial fail-safe mechanisms that direct wastewater flow when lift stations experience issues. However, a common problem arises when these gates remain shut unintentionally, obstructing the flow. Rigorous testing and scheduled maintenance of these gates can prevent such scenarios. Schedule routine inspections with a trusted septic tank repair service for remote monitoring and real-time updates on gate positions to ensure swift corrective actions if needed.

While lift stations might not capture the limelight like treatment plants, they play an indispensable role in managing wastewater. Addressing the challenges of insufficient capacity, inefficiency, elevated discharge, odors, and gate malfunctions requires proactive maintenance, innovative engineering, and collaborative efforts with local authorities. As communities continue to grow, ensuring the reliability and efficacy of lift stations becomes pivotal in maintaining a sustainable and sanitary environment. Contact Septic Connection to help you navigate sewage management’s complexities and contribute to a cleaner, healthier future. We offer various services at competitive rates, such as septic tank installation and maintenance.

When septic problems start, many homeowners look for quick and inexpensive solutions. Online videos, store-bought additives, and advice from well-meaning neighbors can make do-it-yourself septic fixes seem appealing. Unfortunately, septic…

Read moreA septic system is one of the most important—and most overlooked—components of a home. It manages wastewater quietly in the background, so many homeowners assume everything is fine until a…

Read more